Raptor Checkweigher Systems

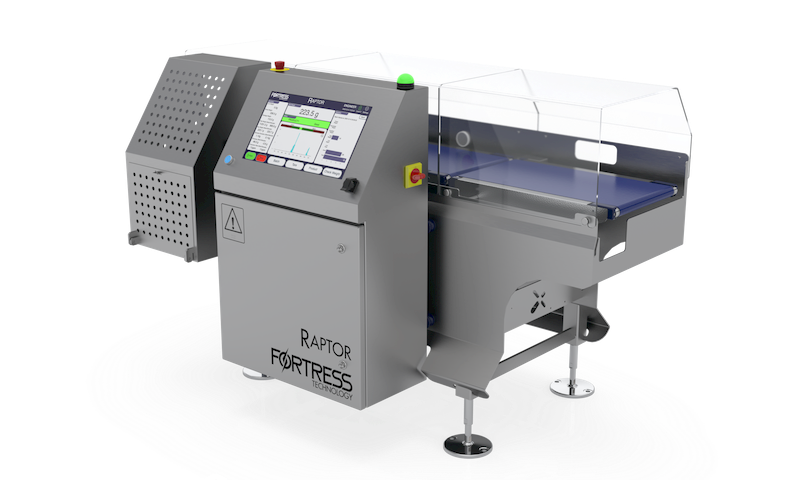

The Raptor is a highly accurate, fully integrated checkweighing system designed explicitly for high-care food production environments.

Raptor Checkweigher

The Raptor is employed to verify the weight of each product and reject non-conforming packs. The system was designed, engineered, and constructed to the highest care/food grade engineering standards. It is capable of processing packaged products up to 8 kg.

Raptor |

KEY FEATURES

|

Raptor BBK Caseweighing System

The Raptor XL is a highly accurate, fully integrated caseweighing system, specifically designed to suit any large bag or case application. The Raptor XL is employed to verify the weight of each product within tolerances or using another weighing system. The Raptor XL has been designed, engineered, and constructed to the highest care/food grade engineering standards.

Raptor XL can be used at any stage in your process to inspect safely, reliably, and accurately 100% of your products. Built-in data collection software with USB data transfer, OPC-UA and Ethernet/IP facilities (optional) allow for ease of production performance tracking and improvement

of operational efficiency.

Raptor XL can be used at any stage in your process to inspect safely, reliably, and accurately 100% of your products. Built-in data collection software with USB data transfer, OPC-UA and Ethernet/IP facilities (optional) allow for ease of production performance tracking and improvement

of operational efficiency.

Raptor Combination System

The Raptor is a highly accurate, fully integrated checkweighing and metal detection combination system, specifically designed for high care food production environments.

The Raptor is employed to verify the weight and inspect for metal contaminants of each product and reject non-conforming packs. The system has been designed, engineered and constructed to the highestcare/food grade engineering standards. It is capable of processing packaged products.

Raptor can be used at any stage in your process to safely, reliably and accurately inspect 100% of your products. Multiple end of line inspection processes can now be carried out, and controlled, within one highly compact system.

The Raptor is employed to verify the weight and inspect for metal contaminants of each product and reject non-conforming packs. The system has been designed, engineered and constructed to the highestcare/food grade engineering standards. It is capable of processing packaged products.

Raptor can be used at any stage in your process to safely, reliably and accurately inspect 100% of your products. Multiple end of line inspection processes can now be carried out, and controlled, within one highly compact system.

|

Raptor Combo

|

KEY FEATURES

|

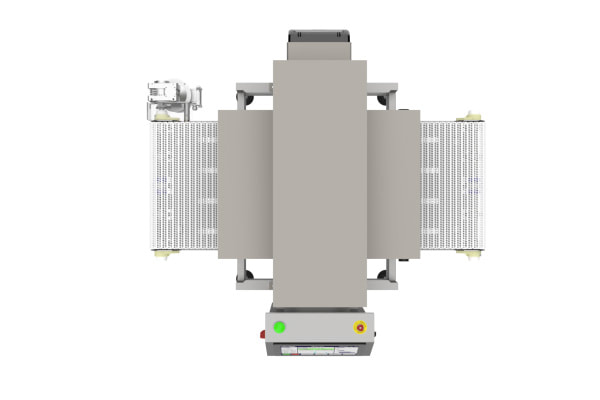

Raptor BBK Combination System (Metal Detection & Checkweighing)

Specifically designed for inspection of 25kg large bags and cases, the Raptor BBK Combination system delivers weighing accuracy and industry leading metal detection performance in one compact footprint.

The Raptor BBK combination metal detector and checkweigher features robust stainless-steel construction incorporating sanitary design concepts suitable for any food manufacturing environment. Ergonomic layout and intuitive HMI enable comfort and ease of use for operators.

The Raptor BBK combination metal detector and checkweigher features robust stainless-steel construction incorporating sanitary design concepts suitable for any food manufacturing environment. Ergonomic layout and intuitive HMI enable comfort and ease of use for operators.

|

KEY FEATURES

|